| Width, outside diameter, inside diameter (key or keyway requirements), and preferred clutch material |

| (2) Torque requirements: |

| Starting and ending tension, line speed, material width |

| (3) Retention System (if required): |

| Type of core or hub you want to mount to our clutch. What is your current retention system? Can you send us an actual |

| sample of the core or hub you want to mount on our clutch? |

| (4) Application/Machine information: |

| What is the manufacturer of your machine? Can we get a sketch of the application? |

|

|

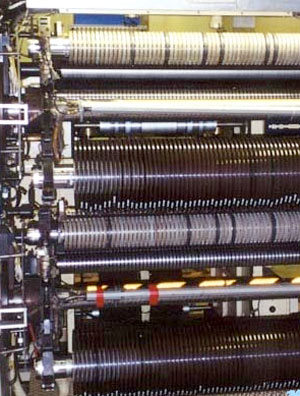

| Typical

Applications:

Generally, eddy current clutches are used for take-up applications on slitting and rewinding machinery. Eddy Current Clutches give very accurate tension control. |

|

|

|

|

| • Accurate tension in ounces or grams |

| • Large bores and narrow widths |

| • No electricity, no slip rings |

| • No break-away torque |

| • No wearing parts |

|

|

|

Eddy Current clutches give torque as a function of RPM. The faster you turn the rotor, the more torque. This means by increasing or decreasing the RPM, you can get infinite torque adjustment. Typically, we rate the clutch with a gain factor (k), which is gram millimeters/rpm or Newton meters/rpm and we design the clutch to have an operating “slip rpm” between 1 and 300 rpm. |

|

|

| At Magnetic Technologies Ltd. we have been building custom eddy current clutches since 1984. We are constantly fine tuning and improving our designs. Today, we have hundreds of custom designed units in use. We have eddy current clutches running on every continent. Because of our maintenance and retro-fit programs, we have a chance to see how our clutches perform over time. Most are still in use even after 15+ years of continual service! |

| Pricing & Delivery: |

| We build all our eddy current clutches to order. Some of the most popular sizes include: |

| (1) 76mm OD; 16 to 50mm wide; 25 to 45mm ID |

| Typical torque gain factor 17 to 100 Gmm/Rpm |

| (2) 152mm OD; 45 to 300mm wide; 50 to 90mm ID |

| Typical torque gain factor 0.020 to 0.142 Nm/Rpm |

| For a price quote, please tell us about your needs and specifications. |

| Required Information: |

| (1) Dimensional Data: |