| How Magtork™ Brakes & Clutches Operate | |

|

|

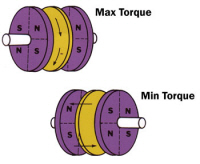

All Important internal

clearances are ground to tolerances of less than 0.025mm (0.001

inch). Magnet assemblies (purple) surround our hysteresis

assembly (gold). When like poles face each other, they produce

maximum magnetic saturation of the hysteresis disc, forcing

lines of flux to travel circumferentially through the hysteresis

disc. This produces maximum torque. When opposite poles face each they produce minimum saturation of the hysteresis disc. This produces minimum torque. Combinations of adjustment angles between the two extremes give infinite adjustability. Because there are no contacting surfaces, the setting can be maintained indefinitely. |

| Why Are MTL Brakes and Clutches Better? | |

|

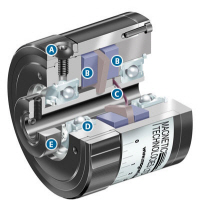

Large, industrial knurled adjustment with socket cap screw for locking the adjustment. Most importantly, the adjustment has positive stops at "0" and "100%". Because we do all our own magnetizing in house, we are better able to control flux density in the magnetic assemblies assuring better adjustability and consistency unit to unit. To eliminate any tolerance build up, we add a special wave spring to take out any accumulated tolerance and to pre-load the bearings with just the right amount of pressure to allow easy adjustment and virtually zero end play in the rotor. Because the bearing is the only wearing part, we go to special lengths to buy the best sealed ball bearings available. We use a special high temperature lubricant to add years of long life. Most manufacturers simply tap the rotor to allow shaft connection. We've learned small rotors need an extra set screw collar, so we've added one, which makes mounting easier for you. More importantly we can now use an oversized set screw to give plenty of thread engagement and guarantee a positive shaft connection. |

|